Piping Design is a critical component of engineering projects and process plants. At IPEC, we excel in the science of piping engineering, developing efficient piping processes that safely transport fluids and gases across industrial plants. An optimally designed piping system can enhance the use of space, ease construction, simplify maintenance and accessibility, and improve the overall performance of piping systems.

Comprehensive Piping Engineering Services

IPEC delivers full piping engineering services, ensuring that every aspect of the piping design meets the highest standards of quality and efficiency. Our services include:

2D / 3D Design

- Hydraulic Design: Flow, velocities, pressure drop

- Piping Specification: Materials, pipe schedule, rating of elements

- Insulation: Thermal losses

- 2D / 3D Piping Routing and Modeling

- Piping Lists

- Mechanical Piping Design: Thickness calculation according to ASME B31.1 / B31.3 / EN13480, etc.

- Isometric Drawings for Construction

- Bill of Materials / Quantities

- As-Built Design

Flexibility Analysis

Flexibility analysis is crucial to ensure the integrity and safety of piping systems under various operating conditions. IPEC provides comprehensive piping flexibility analysis, including:

- Piping Flexibility Analysis: According to ASME B31.1 / B31.3 / EN 13480

- Supports Design: Type and position

- Buried Pipes: Analysis and design

- Check of Allowable Loads on Nozzles: Pumps, static equipment, etc., as per WRC-107

- Dynamic Analysis: Modal, harmonic

Advanced Piping Flexibility Analysis

For more complex piping systems, IPEC offers advanced flexibility analysis, including:

- Finite Element Analysis (FEA)

- Determination of SIF (Stress Intensification Factor): According to B31J for special geometries not covered by ASME B31.1 / B31.3

- Large Diameter or Rectangular Ducts/Pipes: Eigen buckling failure mode analysis

- Special Transition Pieces: Rectangular/circular transitions

- Special Supports Design

- Creep Range Design/Operation

- Cyclic Loads: Fatigue analysis

Stress Analyses

Pipe Stress Analysis

As a globally acclaimed and award-winning provider of piping stress engineering services, IPEC offers practical solutions based on decades of field and design experience. Pipe Stress Analysis is our forte, and our teams have extensive project experience in carrying out the full spectrum of stress analysis services for piping systems and piping flexibility analysis. We conduct detailed piping stress analysis, evaluation, and confirmation of the structural and operational integrity of process piping systems.

Expertise in Various Units

We have successfully undertaken stress analysis of piping systems for various units, including:

Oil and Gas Industry

- Offshore Drilling Platforms: Ensuring integrity under harsh marine conditions.

- Natural Gas Processing Plants: Optimizing systems for high-pressure and high-temperature operations.

- Crude Oil Distillation Units: Maintaining structural integrity in extreme environments.

- Refinery Hydrogen Units: Ensuring safety and reliability in hydrogen production.

- Enhanced Oil Recovery Systems: Analyzing systems for thermal and pressure stresses.

Petrochemical and Chemical Industry

- Polyethylene Production Units: Safeguarding high-pressure reactor systems.

- Ammonia Production Plants: Ensuring reliability under high pressures and temperatures.

- Ethylene Cracking Units: Optimizing networks for thermal and mechanical stresses.

- Specialty Chemical Plants: Enhancing precision in specialty chemical production.

- Fertilizer Manufacturing Facilities: Ensuring efficiency across varied production stages.

Software / Tools / Technology

We utilize advanced software and tools to ensure accurate and reliable stress analysis:

- Hexagon CAESAR II

- Bentley AutoPipe

Industries Served

Our services cater to a wide range of industries, including:

- Oil & Gas

- Petrochemical & Refinery

- Energy & Utility

- Specialty Chemical

- Manufacturing

- Water & Waste Water Treatment

Industry Codes and Standards

Our designers adhere to the following industry codes and standards:

- ASME B31.1, B31.3, B31.4, B31.8, B31.11

- BS EN 13480, BS EN 14364

Service Metrics

- 65,000 Man-Hours of Project Executed

- 15 Years of Team Experience

- ISO 9001 & 27001 Certification

Service Offerings

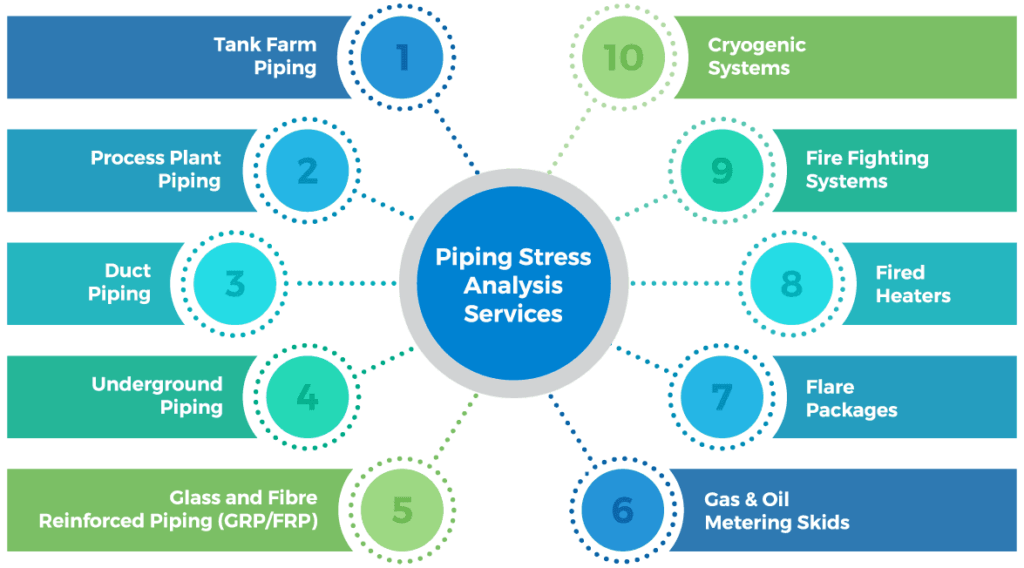

As a pipe stress analysis consultant, we perform pipe flexibility and stress analysis for various piping systems. Our services include:

Piping Stress and Flexibility Analysis Services

- Preparing Support Standard and Support Drawings

- Stress Analysis that meets various code requirements

- Pipe Support Selection

- Equipment Nozzle Check

- Flange Leakage Check

- Fluid Hammer Analysis

- Blast Analysis

- Slug Flow Analysis

- Surge Analysis

- Modal Frequency Check

- Fatigue Analysis

- Weld Strength Check

Why Choose IPEC?

With decades of experience in piping design and engineering, IPEC combines powerful design tools with a commitment to total quality management. Our expertise ensures that piping systems are designed to meet the most demanding standards of safety, efficiency, and reliability.